Corona treatment of PVC film on flat laminating machine is an important method of surface modification, which plays a vital role in improving the bonding performance, printing performance and subsequent processing performance of PVC film.PVC (polyvinyl chloride) is a widely used plastic material, which has a wide range of applications in the fields of packaging, building materials, and electronics due to its excellent physical and chemical properties. However, the non-polar and low surface energy characteristics of the PVC film surface make it often difficult to obtain the desired bonding effect when laminating or printing with other materials. Corona treatment is to solve this problem and is widely used technology.

First, corona treatment can significantly improve the surface energy of PVC film. In the process of corona discharge, the high voltage makes the air ionised, producing a large number of active particles and free radicals. These active particles and free radicals react with the molecules on the surface of the PVC film, destabilising the PVC molecular chain and thus forming polar groups on the surface, such as hydroxyl and carboxyl groups. The introduction of these polar groups increases the surface energy of the PVC film, thereby improving its adhesion to materials such as inks and adhesives.

Secondly, corona treatment helps to improve the printing performance of PVC film. In the printing process, the ink needs to form a good adhesion with the material surface. Due to the smooth surface of the PVC film and low surface energy characteristics, untreated PVC film is often difficult to obtain clear, solid printing results. After corona treatment, the polar groups on the surface of the PVC film can have strong interactions with the polar components in the ink, thus improving the adhesion of the ink, making the printing pattern more distinct and long-lasting.

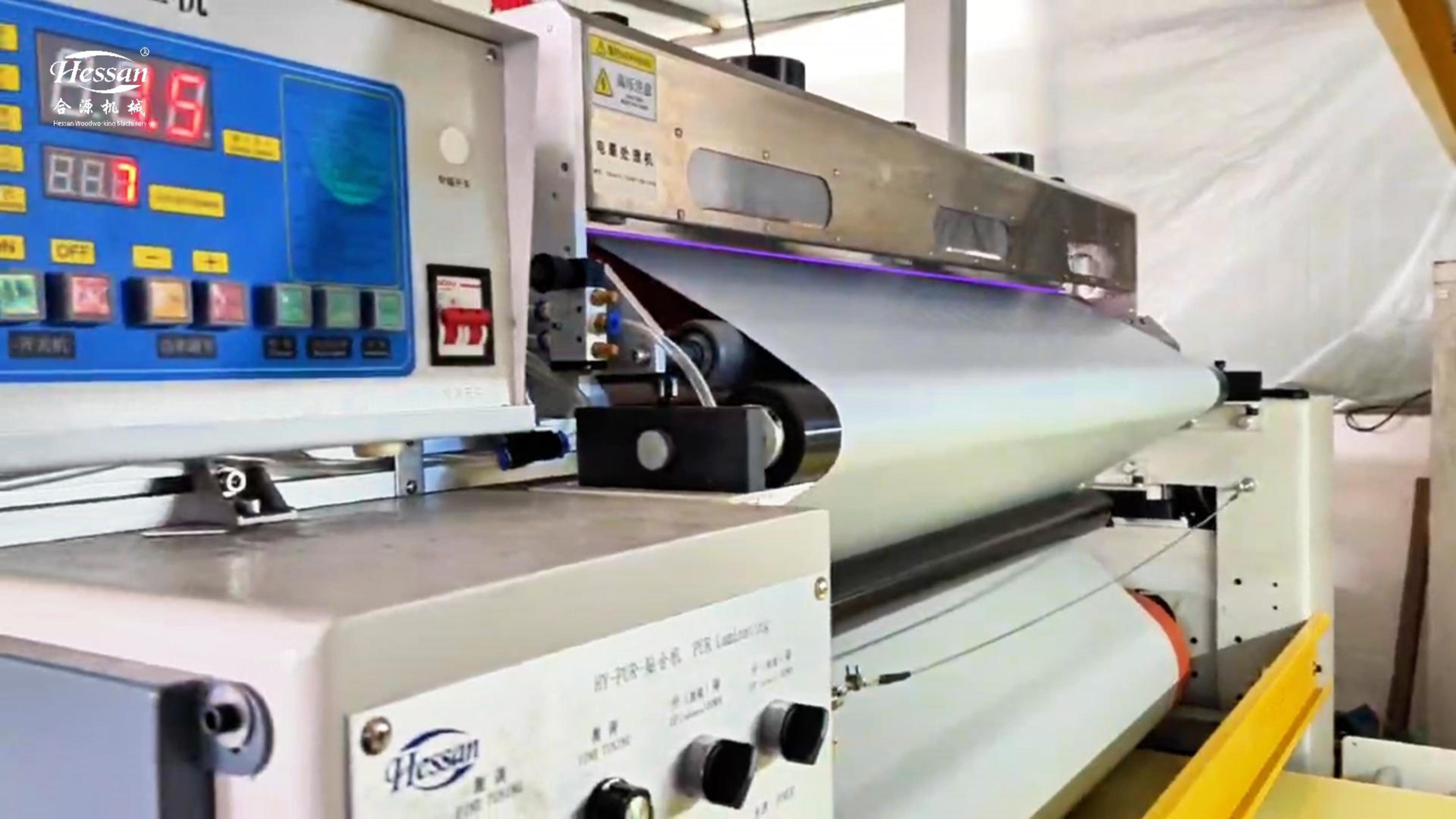

Furthermore, corona treatment is also crucial for improving the composite processing performance of PVC film. In the production process of composite materials, PVC film often needs to be laminated with other materials such as paper, metal foil, etc.. The untreated PVC film surface is smooth, and the adhesive effect with these materials is poor, easy to peel, blistering and other problems. After corona treatment, the polarity of the PVC film surface increases, which can form stronger chemical bonding or physical adsorption with the composite material, thus improving the overall performance and stability of the composite material.

In addition, corona treatment can also improve the weathering and chemical resistance of PVC film. During corona treatment, the polar groups formed on the surface of the PVC film can react with moisture and oxygen in the environment to form a protective layer, thus improving the weather resistance of the material. At the same time, these polar groups can also react with some chemical substances to improve the chemical resistance of PVC film, so that it is more stable when used in some specific chemical environments.

Finally, corona treatment is a cost-effective surface modification technique. Compared with other surface treatment methods, such as chemical treatment and flame treatment, corona treatment has the advantages of easy operation, low cost and high efficiency. It does not require complex equipment and a large number of chemical reagents, and the treatment process has less impact on the environment, which is a green surface modification technology.

In summary, corona treatment plays a crucial role in the application of PVC film. It greatly expands the application range and market value of PVC film by improving its surface energy, printing and laminating processing performance, and weathering and chemical resistance. With the continuous development of material science, corona treatment technology is also progressing, providing more possibilities for the surface modification of PVC film and other plastic materials.