The PUR flat laminating machine has revolutionized industrial lamination processes, especially for

bonding aluminum sheets with PET films. This advanced technology leverages PUR glue (Polyurethane Reactive Adhesive)

to create durable, high-performance composites used in industries like automotive, construction, and packaging.

In this article, we’ll explore how PUR flat laminating machines work, why aluminum sheet PET lamination is critical,

and the advantages of using PUR glue over traditional adhesives.

1. What is a PUR Flat Laminating Machine?

A PUR flat laminating machine is a precision-engineered system designed to bond materials like metals, plastics, and films using PUR glue. Unlike standard laminators, PUR machines apply heat-activated adhesives that form ultra-strong, flexible bonds resistant to moisture, chemicals, and temperature extremes.

Key Features:

Precision coating of PUR glue for even adhesion.

Heated rollers to activate the adhesive.

Adjustable pressure for aluminum sheet PET lamination without warping.

2. Why Use PUR Glue for Aluminum Sheet PET Lamination?

PUR glue is the preferred adhesive for PET lamination on aluminum sheets due to its unique properties:

Advantages of PUR Glue:

✔ Superior Bond Strength: Creates permanent bonds between aluminum sheets and PET films.

✔ Flexibility: Withstands bending and machining without delamination.

✔ Resistance: Immune to humidity, UV rays, and solvents.

✔ Eco-Friendly: Low VOC emissions compared to solvent-based adhesives.

Industries use PUR flat laminating machines for this process to ensure consistency and high throughput.

3. Applications of Aluminium Sheet Laminated with PET Film

Aluminium sheets laminated with PET film are widely used in:

A. Automotive industry

Interior panels (lightweight, scratch-resistant surface).

B. Architecture

Decorative cladding (weatherproof, aesthetic finish).

C. Furniture

Tables, Cabinets, Refrigerator Doors (beautiful, scratch-resistant finish for longer life).

Luxury enclosures (high quality metal finishes).

PUR flat laminators ensure that these composites meet industrial durability standards.

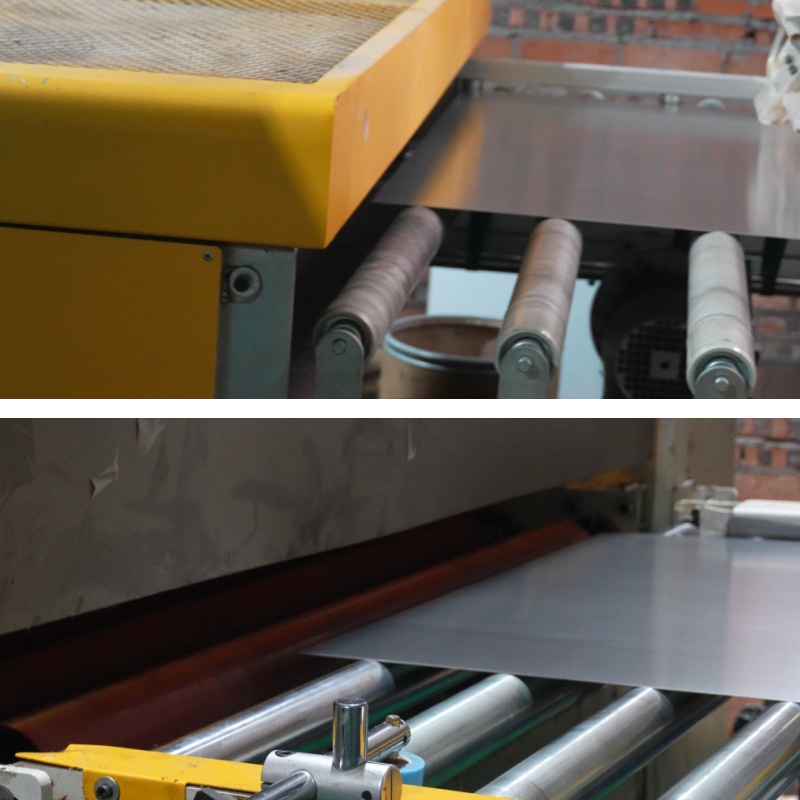

4. How the PUR lamination process works

Step-by-step workflow:

Material preparation:

Cleaning of aluminium sheets to remove oils/oxides (using an acid washer).

Pre-treatment of the aluminium sheet to prevent blistering.

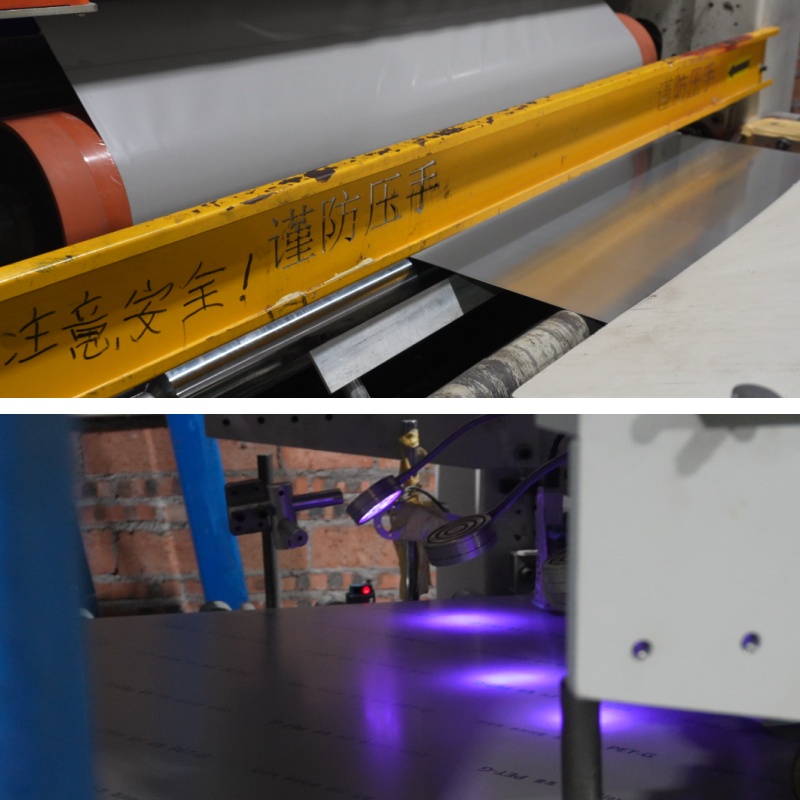

Application of PUR adhesive:

The PUR flatbed laminator applies a thin, uniform layer of PUR adhesive to the aluminium sheet.

Pressing stage:

Under heat and pressure, the PET film is pressed onto the adhesive coated aluminium sheet.

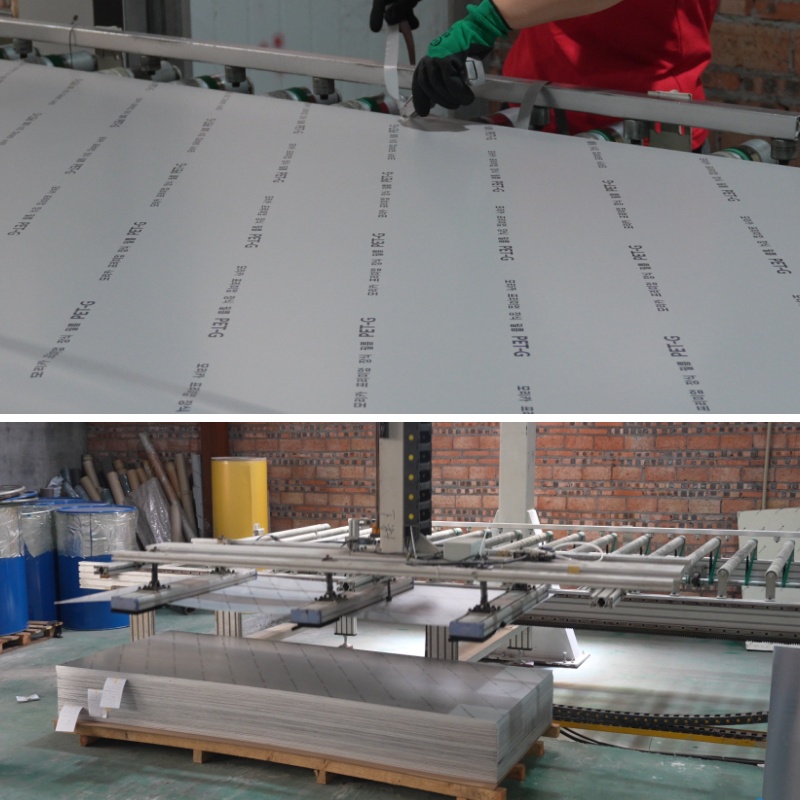

Curing and finishing:

The bonded laminates are cooled, trimmed and inspected.

This process ensures that the PET laminate is bubble-free and wrinkle-resistant.

5. Why Choose a PUR Flat Laminating Machine Over Alternatives?

| Feature | PUR Flat Laminating Machine | Traditional Laminators |

| Adhesive Type | PUR glue (reactive, strong) | Solvent-based (weaker bond) |

| Speed | Faster curing (↑ productivity) | Slow drying time |

| Durability | Resists peeling/heat | Prone to delamination |

| Eco-Impact | Low VOC, sustainable | High VOC emissions |

For aluminum sheet PET lamination, PUR technology is unmatched.

Conclusion

The PUR flat laminating machine is a game-changer for aluminum sheet PET lamination, offering unmatched

bond strength, efficiency, and sustainability. Whether for automotive, furniture,construction, or packaging, PUR glue ensures

long-lasting, high-quality results.

Interested in integrating PUR technology? Contact us for a demo or technical consultation!